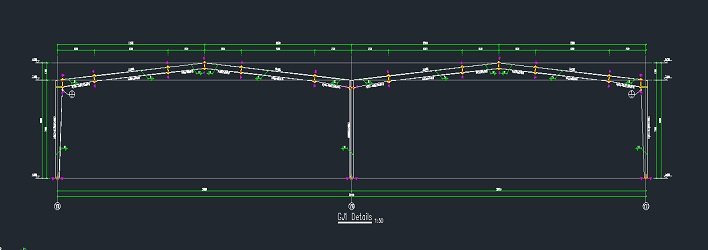

Design and Application of Portal Frame in Steel Structure Workshop

I. Design and Application of Portal Frame Steel Structure

1. Column grid design requirements

The steel structure design of workshop should first determine the column grid construction according to the production process requirements, try to meet the requirements of production and use, and determine the column grid according to the actual situation on the span, height and design practice of the steel frame. The following conclusions were obtained when using the steel frame column grid: under the condition of complete and consistent load, the height of the eave height is 6m, the column distance is 7.5m, the unit span distance of the steel frame is between 18 meters and 30 meters, and the steel consumption is about 18 to 28 kg/m2, when the distance between the unit steel frame span is about 21 to 48 meters, the steel consumption is 25 to 40 kg/m2. The height of the workshop is 12m, and the multi-span type steel frame is generally available when the span reaches 48m or more. Compared with the single-span type steel frame, the steel consumption is saved by 18%. Therefore, the economical span should be selected according to the actual situation in the design of the portal steel frame structure.

2. The loads acting on the portal frame steel structure generally include: vertical and horizontal loads, and seismic loads.

3. Calculate the internal force of steel frame side shift

(1) Calculating internal force method: For portal variable cross-section steel frame structure, various internal forces are determined by elastic analysis method, and plastic analysis method is used only when the steel frame has all steel columns of equal cross-section. The variable cross-section calculation of the internal force of the portal steel frame generally uses the element rod system finite element method. The effect of the earthquake can be determined using the shear bottom method. Analyze the internal force results according to the different combinations of loads, find out the internal force combinations with controlled cross-sections, and control the position of the cross-sections at the bottom of the column connecting the top of the column and the cross section of the beam span.

(2) Method of calculating side shift: The side shift caused by the top of the variable cross-section column of the portal steel frame should be determined by elastic analysis. The standard load value is obtained during the calculation process, and the shared load factor does not need to be considered.

4. Set up Pulling straps, purlins and Sleevings

(1) Purlin design: The purlin is a curved bidirectional structural member. The analysis of its internal force should be based on the calculation of the bending moment of the two core main shaft sections. During the design process, the strength, overall stability and deformation of the purlin should be calculated. When designing the purlin process, it is necessary to control the width of the thin-walled cold-formed member of the purlin, the width ratio of the plate under compression and compression, the buckling that should be maintained when the force is generated, and the effective width that should be reasonably used when calculating the strength. At the same time, the net section should be used when calculating the strength, and the weakening nail hole can be considered.

(2) Pulling strap design: Whether the pulling strap is set or not depends on the lateral stiffness of the purlin. For the larger lateral stiffness of H-shaped light steel and truss-type space purlins, pulling strap are usually not provided. For the side solid web and truss flat purlins with relatively poor rigidity, in order to reduce the lateral deformation generated during the installation and application of the purlins and maintain the stability of the whole, the pulling straps are usually set between the purlins as a lateral support point. When the purlin has a span within 4 meters, the final result of the calculation can be used to determine whether the pulling strap is set or not. When the purlin has a span beyond 4 meters, a pulling strap is suitable for the mid-span purlin.

(3) Sleeving design: The important role of the sleeving is to bend the side purlin upward or downward to the position of the skylight gap and the eaves purlin. The length and slender ratio of the sleeving can be made of steel pipes and angle steels according to the actual requirements of the sleeving.

II. Attention in the design and application of portal frame steel structure

1. Control the verticality of the ridge

The limit deflection of the vertical inclined beam of the frame is generally specified as 1/180. In the past, whether the centering sag was checked was not clearly stipulated, but according to the new regulations, calculations are required. Generally, components are calculated in sections, and calculations are carried out using equal sections. Each section needs to be calculated horizontally and vertically. It cannot be larger than the allowable value, which is equivalent to the implementation of the mid-span sag.

2. The combination of concrete column and steel column

In the steel structure design of the portal steel frame, part of the inclined beam is combined with the concrete column. The inclined beam adopts the pre-embedded bolts of the end plate to connect the concrete column to save steel and cost. In the portal frame steel structure, the frame has a combination of steel columns and concrete columns. In this case, the beams and columns can only be hinged, which is not suitable for steel connection and it is the same for steel wall connections in high-rise buildings. Therefore, it should be noted that the combination of steel beams and concrete columns is allowed for the bent frame, but it is not allowed to replace the steel columns in the rigid frame with concrete columns without changing the steel beams.

3. Calculation problems in purlins

The purlin is a cold-formed structural part, and the pressure-bending or pressure-bearing plate has a relatively large width ratio. It should be buckled when the force is generated and the effective width should be used to calculate the strength and the original cross-section needs to be weakened to achieve effective in all sections. According to relevant regulations, the tensile strength of steel frame members shall be calculated based on the net section, the compressive strength shall be calculated based on the effective section, and the stability characteristics shall be calculated based on the effective section.