PEB building construction steps

PEB or Pre-Engineered Buildings are a popular choice in the construction industry today due to their speed of construction, low cost, flexibility, and durability. These buildings are made of prefabricated components that are engineered and fabricated in a factory before being shipped to the construction site for assembly. PEBs can be used for a variety of purposes such as warehouses, factories, offices, schools, hospitals, and even residential homes. In this article, we will discuss the step-by-step process of constructing a PEB building.

Step 1: Site Preparation

The first step in the construction of a PEB building is site preparation. The site needs to be cleared of any obstructions and leveled to provide a flat surface for the construction of the building. Any underground utility lines need to be marked and protected to avoid damage during construction. A temporary construction office and storage area are set up on the site.

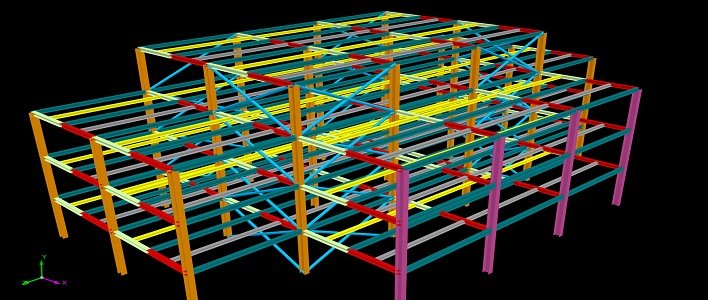

Step 2: Design and Engineering

Once the site is prepared, the design and engineering of the building begin. The design and engineering of a PEB building involve creating a 3D model of the building that includes all the structural components such as columns, beams, purlins, and bracing. The model is then analyzed using computer software to ensure that the design is structurally sound and meets all the building codes and regulations.

Step 3: Fabrication of Structural Components

Once the design and engineering are completed, the fabrication of the structural components begins. The columns, beams, and purlins are fabricated from steel coils that are cut to size and shape using computer-controlled machines. The components are then welded, bolted, or riveted together to form the frame of the building.

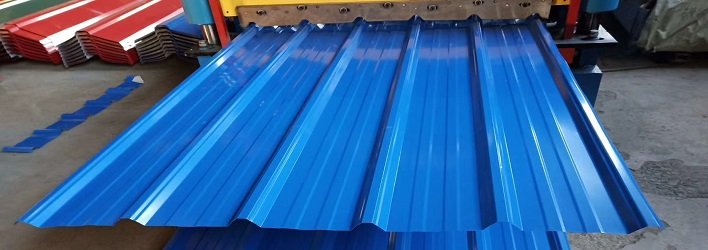

Step 4: Fabrication of Roof and Wall Panels

The roof and wall panels of a PEB building are also fabricated in a factory. The panels are made of high-quality steel sheets that are coated with a protective layer to prevent corrosion. The panels are cut to size and shape using computer-controlled machines and then assembled to form the roof and wall panels.

Step 5: Transportation to the Site

Once the structural components, roof, and wall panels are fabricated, they are transported to the construction site. The components are loaded onto trucks and shipped to the site where they are offloaded and stored in a secure area.

Step 6: Foundation and Anchor Bolts

Before the assembly of the building begins, the foundation and anchor bolts are installed. The foundation is typically made of concrete and is designed to support the weight of the building. The anchor bolts are embedded in the foundation and are used to attach the structural components of the building to the foundation.

Step 7: Erection of Structural Components

With the foundation and anchor bolts in place, the erection of the structural components of the building begins. The columns are first erected and then the beams and purlins are attached to the columns. The bracing is installed to provide lateral stability to the building.

Step 8: Installation of Roof and Wall Panels

Once the structural components are erected, the roof and wall panels are installed. The panels are attached to the frame of the building using self-drilling screws. The panels are overlapped to provide a weather-tight seal.

Step 9: Electrical and Plumbing

After the installation of the roof and wall panels, the electrical and plumbing systems are installed. The wiring and piping are installed in the walls and ceilings of the building. The electrical and plumbing systems are connected to the main supply.

Step 10: Doors, Windows, and Finishing

The final step in the construction of a PEB building is the installation of doors, windows, and finishing. The doors and windows are installed in the wall panels. The finishing includes painting, flooring, and insulation.